Ericsson-LG Enterprise observes Sustainability Policies in order to contribute to the sustainable advancement of society and provide products and solutions delivering high environmental performance.

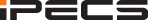

ISO 14001 is widely used in communication with stakeholders as the global standard for environmental management. Ericsson-LG Enterprise obtained ISO 14001 in 2009 to minimize, and to manage efficiently, environmental impacts related to business. We have been striving for systematic and continuous management by introducing an environmental management system based on ISO 14001.

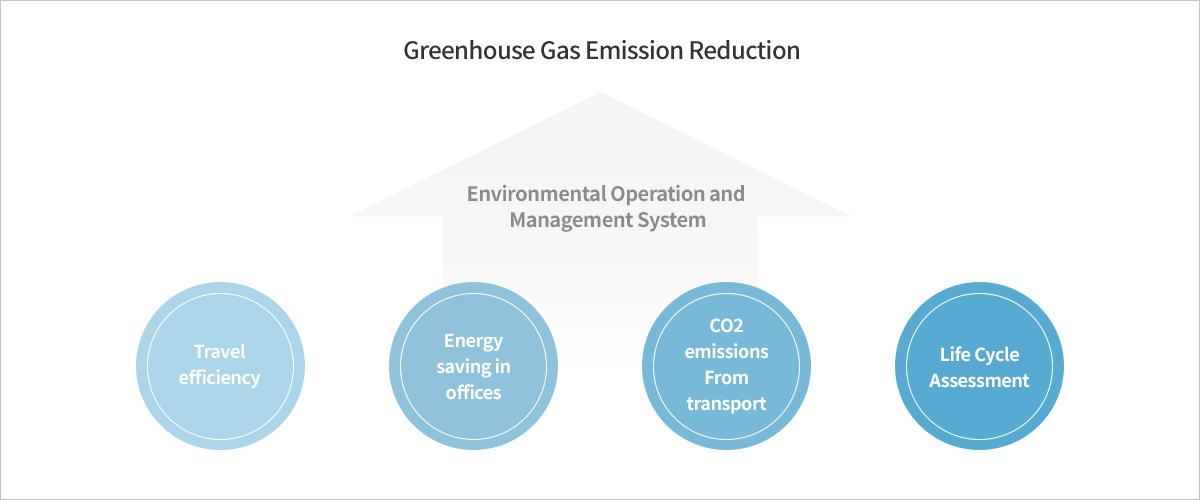

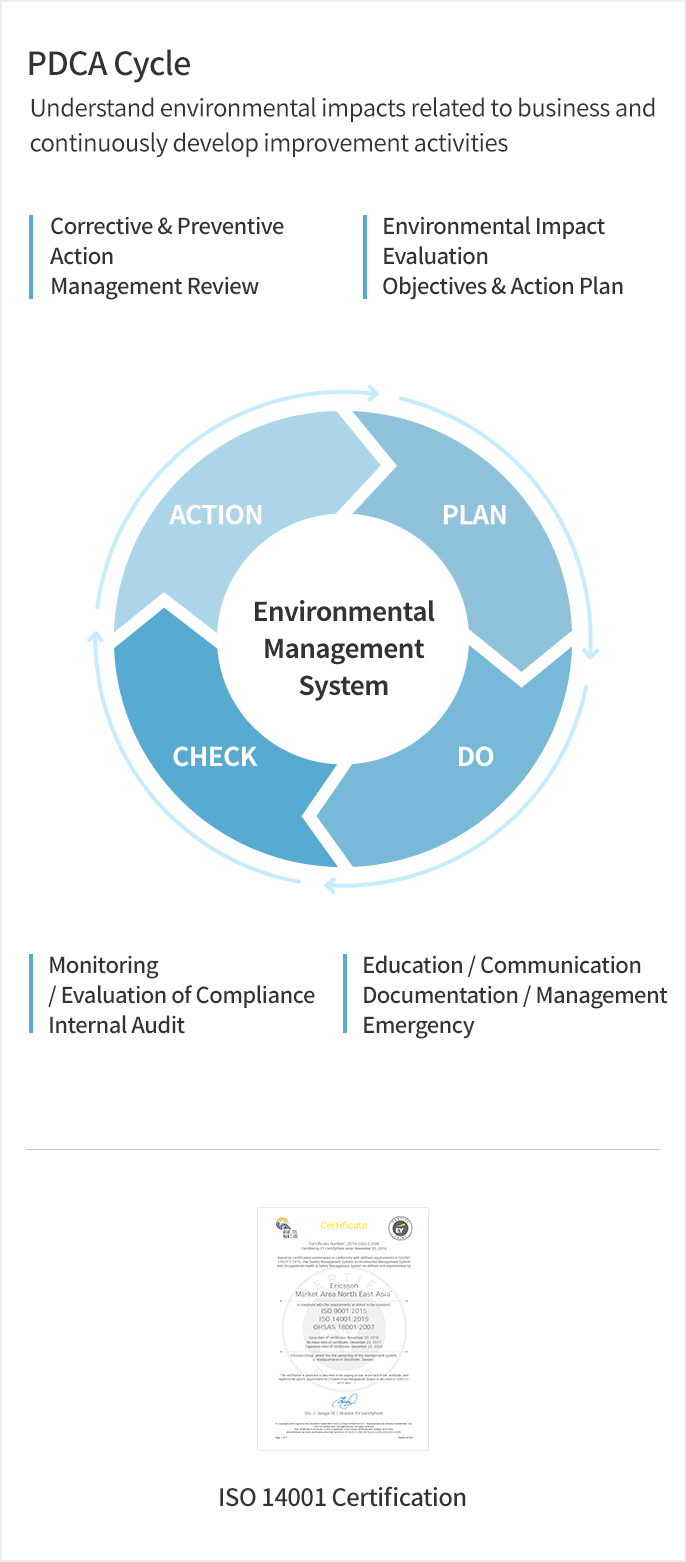

Though it is not a company that emits direct pollutants, Ericsson-LG Enterprise recognizes the importance of addressing the problem of climate change as a communication equipment company. We have been carrying out greenhouse gas reduction activities since 2011, placing emphasis on 4 areas: travel efficiency; energy saving in our offices and facilities; CO₂ emissions from our product transport; and control of CO₂ emissions across all processes from the product manufacturing phase to disposal.

Travel Efficiency

Ericsson-LG Enterprise determines the expected greenhouse gas emissions of business travels of employees and continuously makes efforts to reduce emissions through efficient use of transport and intelligent use of technology. In 2009, video conference systems were built in all domestic and overseas business places. Smart work solutions such as web conferencing and individual audio conferencing were also adopted in 2011.

Energy Saving in Office

The greenhouse gases emitted by the business premises of Ericsson-LG Enterprise are those generated by two energy sources: electricity and gas. Last year, we improved the energy efficiency of the air inflow control equipment in the Data Center, one of the places with the biggest energy consumption in the office. We are also planning to have energy-saving activities concentrated in STP and LAB in the R&D Center, the place with the biggest energy consumption.

Carbon Footprint Labeling Certification for Product

Ericsson-LG Enterprise understands the environmental impact wielded by products and makes efforts to reduce the emission of greenhouse gases. We acquired Carbon Footprint Labeling Certification by evaluating the entire manufacturing process of VoIP phone sets on a trial basis. Carbon Footprint Labeling Certification means indicating on the product the total quantity of CO2 emitted in all processes from production, distribution, and consumption of a product to disposal. Certification in the field of office phone sets was carried out by Ericsson-LG Enterprise for the first time in Korea.

As Ericsson-LG Enterprise develops environmentally friendly products, it responds in a timely manner to domestic and international environmental regulations and control and minimizes environmental impact by accounting for environmental aspects in the life cycle of products.

Energy Efficiency Enhancement of Products

Ericsson-LG Enterprise applies the “Energy Efficiency Design Check Sheet” it developed to improve the energy efficiency of products. We also observe the ErP Directive to minimize standby power. In addition, we participate in the ESP (Energy Standby Program) operated by a government organization (Korea Energy Management Corporation) to reduce standby power usage.

Verification of Environmentally Friendly Products

Ericsson-LG Enterprise not only evaluates autonomously whether a product is an environmentally friendly product at the development phase of the product but also assesses the inflow of hazardous substances periodically at the production phase using an external third-party certification institute.

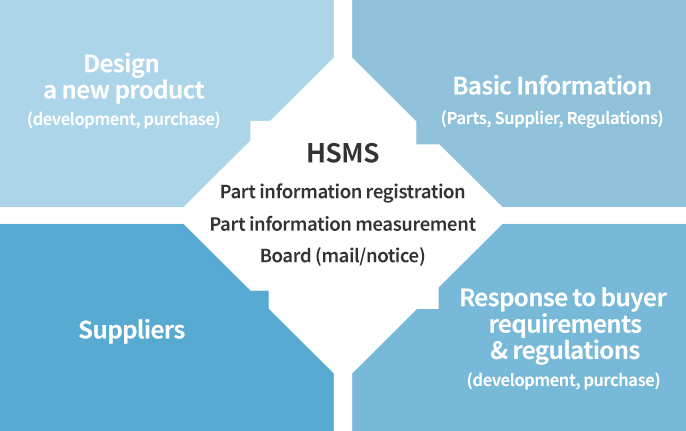

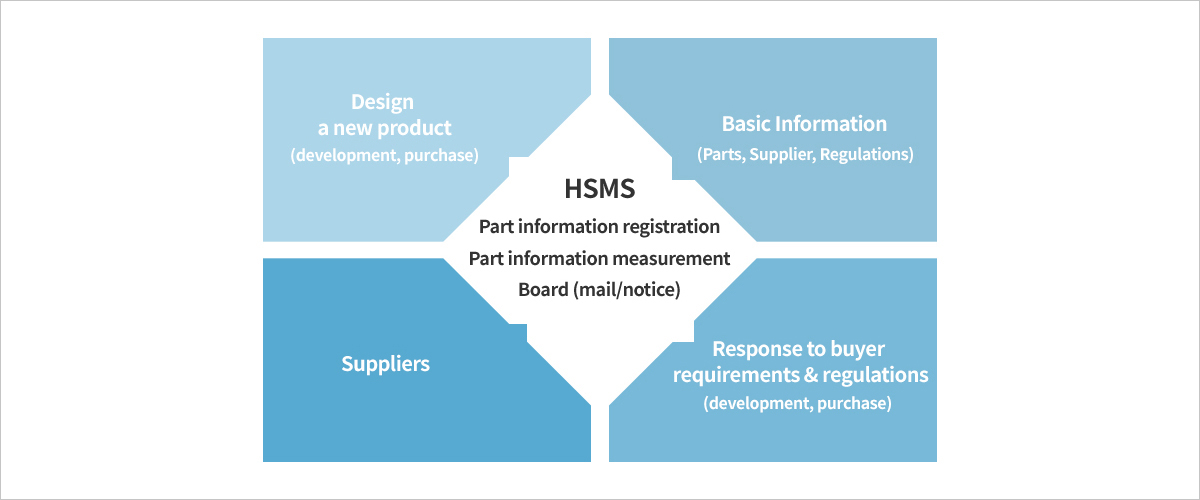

Hazardous Substance Management

Ericsson-LG Enterprise operates an IT system that it developed to manage information on the use of hazardous substances (HSMS: Hazardous Substance Management System). HSMS efficiently manages information on the hazardous substances contained in raw materials and parts. Furthermore, we require suppliers to prepare analysis reports for parts at the product development phase and manage whether hazardous substances are used or not in accordance with the management standard of each supplier.